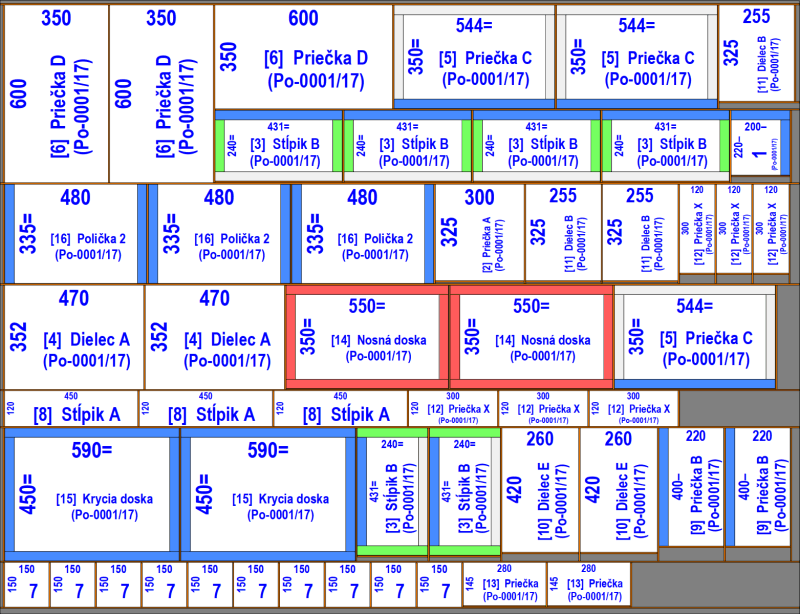

Any cutting direction

Any cutting direction Longitudinal cuts

Longitudinal cuts Cross cuts

Cross cuts

OPTIMIK contains a powerful optimization algorithm which quickly proposes optimal cutting plans for the specified parts. The calculation can be influenced by setting various parameters, such as the kerf, the method of dividing by cutting, the width of the trimming of material edges, etc. If several material formats are available, OPTIMIK can select the most suitable ones. In addition to the best possible use of the material, OPTIMIK tries to group the waste as much as possible so as to create larger usable cut-offs from it. These are then automatically included in other cutting plans.

OPTIMIK can also calculate cutting plans for very large numbers of parts in a short time.